Our materials

Red Bronze

Red Bronze or White Bronze

Bronze is an alloy composed largely of copper.

In a quality approach, we use at least 65% copper for our alloy.

The composition can be up to 95% copper. The remaining 5% is usually tin,

which will change the color of the bronze in different shades from white to red.

We guarantee a lead-free composition in all our alloys.

Brass

Brass is a compound alloy,

like bronze, a significant amount of copper.

The difference with a bronze alloy is the addition of zinc.

This alloy thus offers a better hardness,

which increases its mechanical strength.

Brass

Our processes

The lost wax

Lost wax is a precision casting process for

obtain a metal sculpture (such as silver, gold, bronze, copper)

from a wax model.

The original wax model is coated with several layers

refractory material (cement or plaster) and iron reinforcement.

After solidification of the coating, the wax is evacuated by heat,

the mould is thus made.

Vents are created on the mold, in strategic places that allow both the evacuation of air and a good distribution of matter in the details.

The hollow mold is filled by the molten bronze via the casting cone.

Once the bronze has cooled and solidified, the mould is mechanically destroyed to recover the example made.

The part is then cleaned and cleared of casting rods and vents.

This technique is used for the realization of parts

unique glass or metal.

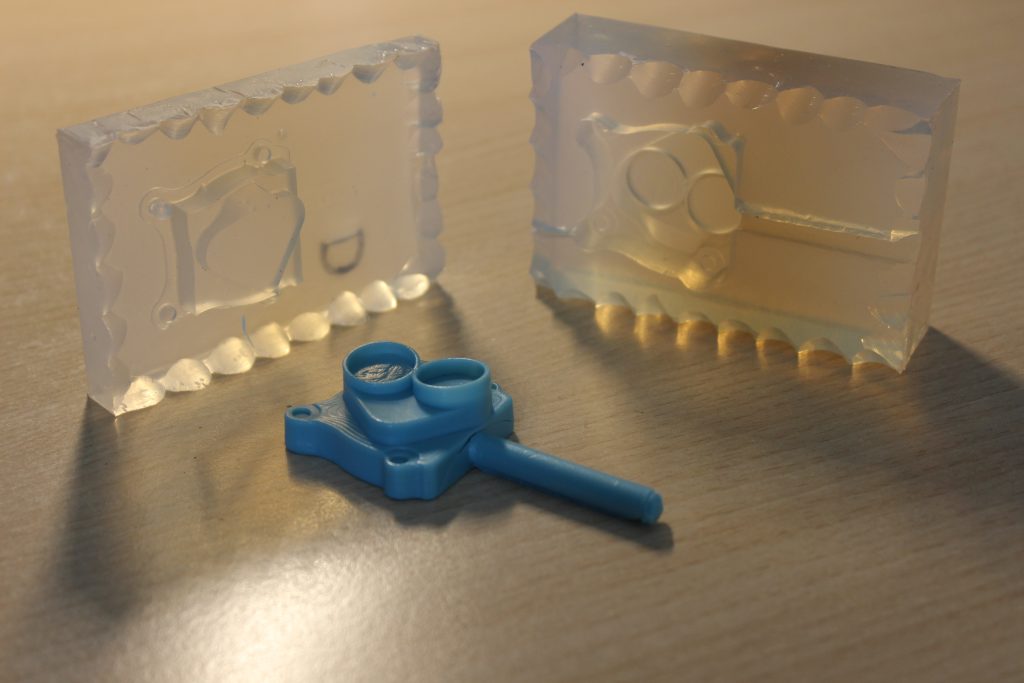

It is however possible to make several waxes from the wax

original using a soft mold, formerly gelatin, now silicone.